תיאור

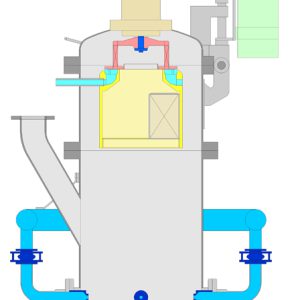

The new generation of PRK Agitator Mills is a further development of the proven NETZSCH Attritor machine.

For the first time these batch mills allow you continuous circulation grinding of hard and abrasive products. A compressed air diaphragm pump discharges the product and is used for circulation during operation.

You achieve highest product qualities with exact reproducibility.

• Special agitator, vertically arranged, with tungsten carbide sleeves as wear-protection for the agitator pegs, activates the grinding media

• High shear and bouncing forces are obtained by optimising the agitator shaft design according to the grinding media size used

• Ideal flow conditions inside the grinding tank by adapted agitator peg arrangement in combination with a semi-spherical tank floor

• Hard metal sieve plate for product grinding separation in the tank floor

• Discharge valve with filter

• Intensive cooling by double-wall grinding tank and coolable circulation pipeline

• Condensation cleaning on the coolable tank lid

• Circulation grinding guarantees exact reproducibility and high product homogeneity

• Residue-free discharge and easy cleaning due to dish bottom chamber

• Enclosed machine design to prevent emissions

• Better servicing, due to integrated swivel-type grinding chamber mobile on rails and pneumatic lifting device for tank cover

• Symmetrically arranged pegs allows reverse rotation to increase the machine’s lifetime

• Coolable grinding chamber

Options

• Automation of production and cleaning process by PLC control

• Adjustable agitator shaft speed