תיאור

Fresh creative standards were also set for the new Alpha® from the very beginning and a new expression of form was used that distinctly communicates the innovative strength of NETZSCH in the design as well. In place of the cast housing, external instruments and pipework there is a clear, dynamically-curved welded construction of heavy plating which also fulfills a load-bearing function.

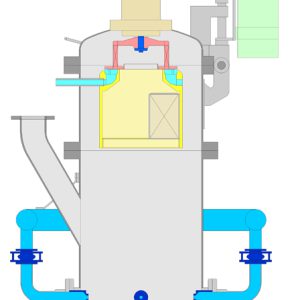

The ergonomic design of the machine stand was a primary consideration during the development phase. The Alpha®has a self-supporting grinding chamber, which ensures good accessibility to the grinding area during operation and maintenance. Thanks to the ergonomic mounting of the grinding chamber, changing products is quite easy, especially on the smaller models.

The new Alpha® sets the standard when it comes to flexibility and handling and, thanks to its modularity, allows customer-specific solutions: different grinding systems can be mounted on one base stand – customized for the requirements of the product you need to process.

The advantage this modular system brings you is cross-system standardization and thus the option to economically convert a machine to a new grinding system. In addition, the Alpha® is also the platform for future NETZSCH technologies, which guarantees you long-term investment security.

Three different grinding systems

System Discus

The Revolutionary, Universal Grinding System

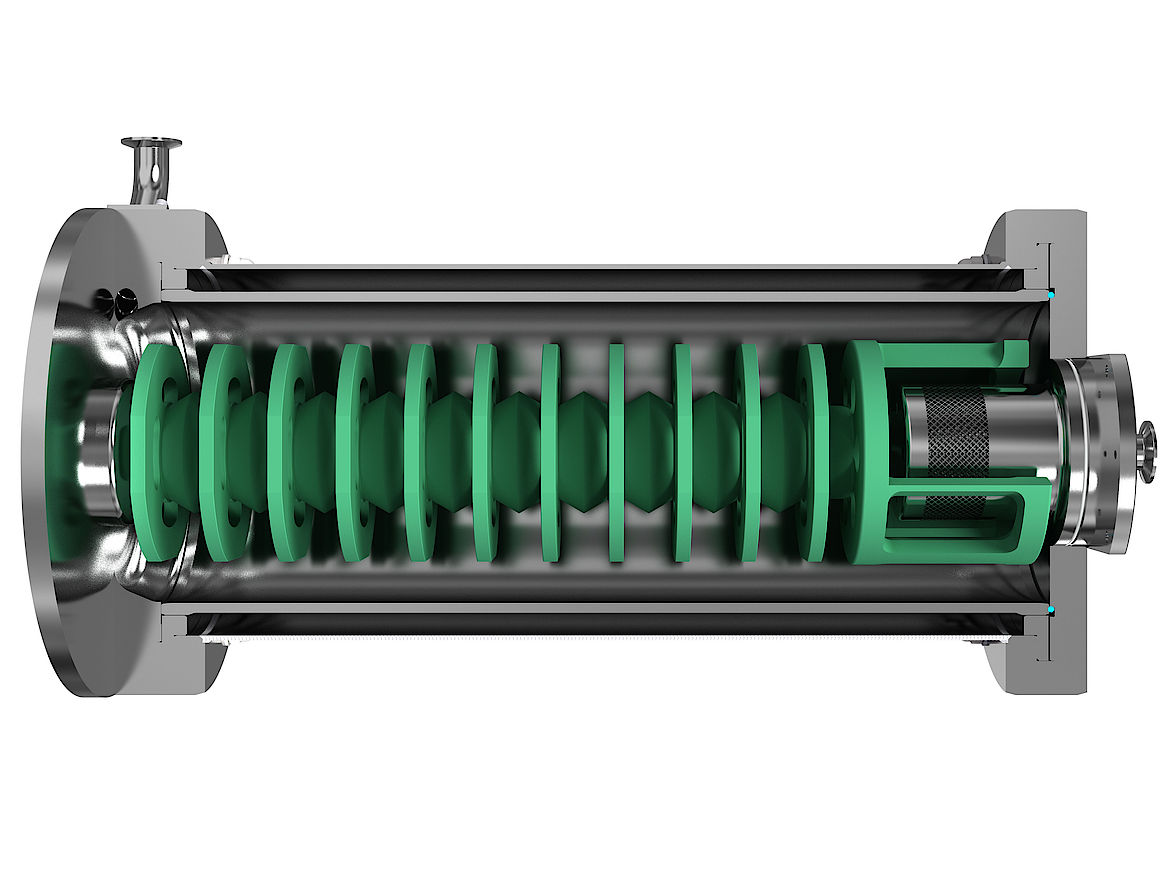

The NETZSCH Alpha®Discus system is the quantum leap in disk grinding technology. The further optimized Discus disk agitator combined with the NETZSCH DCC® separation system guarantees you extremely high throughput rates with significantly narrower dwell time distributions and therefore more intensive grinding with uniform impact intensity. The power input of the mill increases considerably, with a simultaneous increase in energy efficiency. The Discus grinding system activates and optimizes the movement of the grinding beads between the disks, which leads to a higher power input and a grinding efficiency with low specific energy consumption. Thus, you profit from a significant reduction in production costs, since the specific energy consumption decreases with increasing productivity.

NETZSCH Alpha®Discus System Brings you:

- Extremely high throughput rates

- Significantly narrower dwell time distribution

- More intensive grinding with uniform impact intensity

- The highest power input

- Low specific energy consumption

System Zeta®

The Grinding System for Circulation and Multi-Pass Operation

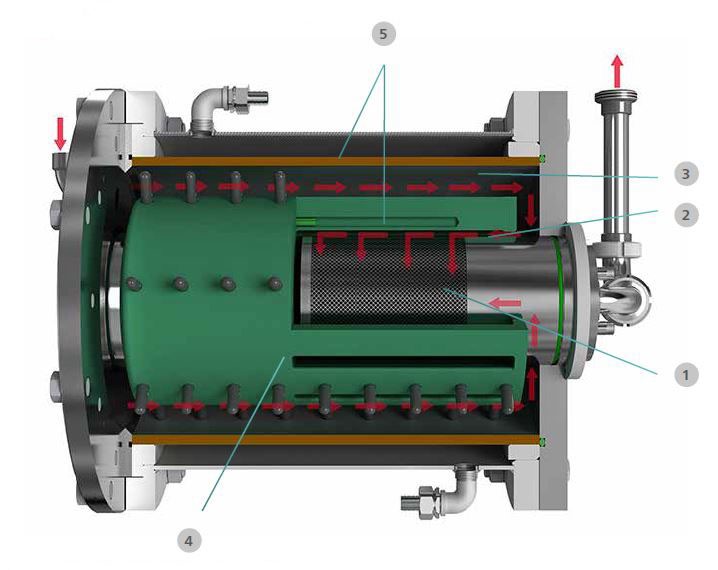

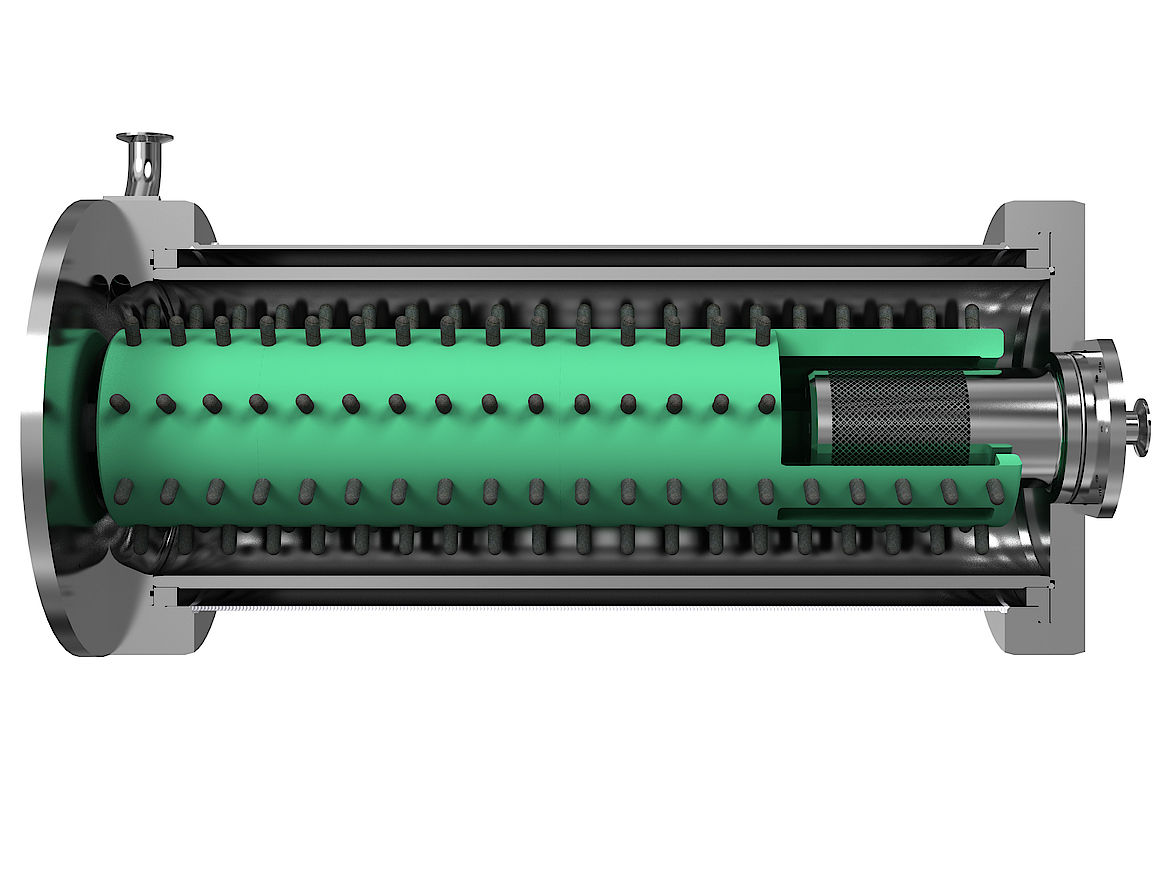

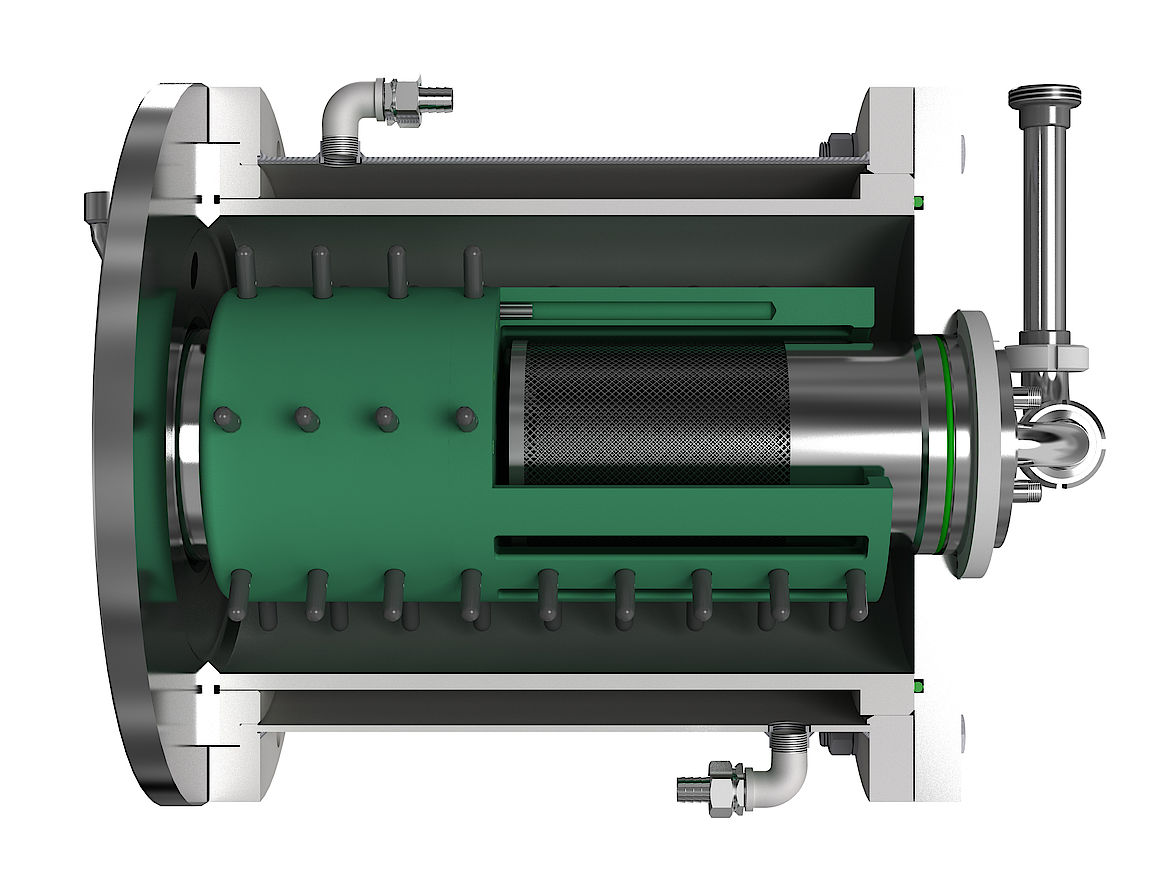

Suitable for every viscosity and almost any product, with this technology you will achieve the highest product qualities and finenesses into the nanometer range using a wide variety of grinding media from 0.1 mm to 3 mm in diameter. The closed horizontal agitator bead mill is designed for the highest product throughput rates and has a peg grinding system with extremely high grinding intensity.

Focus on Your Benefits

- Peg grinding system with the highest grinding intensity

- Finenesses into the nanometer range

- Narrowest particle size distribution

- Greatest cost efficiency

- Exact reproducibility

- Effective centrifugal separation system

- Use of extremely small grinding beads from 0.1 mm diameter

- Logical design for the highest throughput rates

- Ideal for circulation/multipass operation

- Optimal energy input with effective cooling

- Ideal temperature control

- Universally applicable for every product

- Scale-up possible from laboratory to production machine

- Reliable use of a wide variety of grinding media from 0.1 mm to 3 mm

- You achieve the best product qualities with maximum output and optimal energy efficiency

- Additional product-optimized grinding chamber configurations available upon request

System Macro

The Grinding System for Maximum Power Input in Passage Operation

The Macro grinding system represents the logical advancement of the John System annular chamber mill with the centrifugal force separation device. The new peg system is designed for high power input in single and multi-pass operation. The grinding system has an intensive cooling system for the grinding chamber and agitator shaft, making the Alpha®Macro System the ideal machine for moderate to high viscosity products, such as UV systems, at low processing temperatures.

Grinding System Neos

Performance and Efficiency – more than a step ahead!

The agitator cooling with the newly-developed Neos grinding system stands for maximum performance, product quality and efficiency. Coupled with the reliable use of extremely small grinding media, you can achieve your required product quality with high production output and low specific energy consumption.

During the design phase, particular attention was given to achieving maximum cooling efficiency. As a result, it is possible to stay within the required temperature limits even with high power input. This means a significant increase in production output compared to similar grinding systems.

- Maximum slotted pipe surface area

- Optimized grinding media separation

- Maximum cooling surface to grinding chamber volume ratio

- New rotor design for efficient power input

- Optimum grinding chamber cooling with NETZSCH-Ceram C inner tank and optional rotor cooling

- The highest power input without overheating the product

- Maximum volume throughput

- The highest cooling efficiency

- Use of extremely small grinding beads (0.1 to 0.8 mm)

- Reproducible product quality

- High degree of process reliability

- Low operating costs

- Conversion of existing machines to the latest technology