תיאור

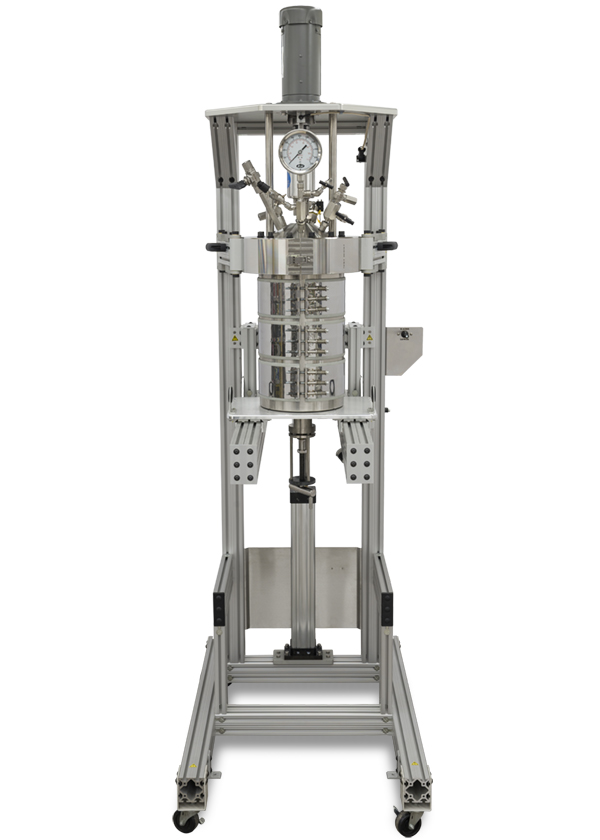

The Model 4555 and 4557 Reactors with their 5 gallon (18.75 L) capacity are the largest stirred reactors offered by Parr. The 4556 and 4558 Models are similar units with a 10 liter (2.6 gal) volume which falls between the larger 5 gallon design and the smaller 1 and 2 gallon models in the 4550 Series. Vessel styles are offered in a moveable head or fixed head design.

These reactors are available with an FKM O-ring seal for operating temperatures to 225 °C, and FFKM O-ring for temperatures to 275 °C, or with a flat, PTFE gasket for operating temperatures up to 350 °C maximum.

In the moveable head design, the vessel is held in a support system which minimizes the physical effort required to handle these heavy components. The hoist is attached to a support column which provides a convenient means for lifting the head and cylinder out of the stand. These components may be transferred to the holding position on the right side of the stand. Vessels equipped with a bottom drain valve will probably remain in the heater most of the time, but can be lifted out when necessary.

The fixed head support stand features hinged split-rings that swing to either side allowing the head to remain fixed to the stand while a pneumatic lift allows the cylinder to be raised and lowered. When lowered, the cylinder can be slid forward for cleaning and servicing.

These reactors are generally used for pilot plant or for custom chemical production purposes, usually with a variety of attachments added to the basic units. Various heaters, larger motors, heavier stirrer drives and remote controls appropriate to the size of these reactors have been designed and are available. Modified versions of these units are available with higher working pressures and temperatures.

| Model Number | 4555 | 4556 | 4557 | 4558 |

| Approximate Volume, mL | 5 (18.75) | 2.6 (10) | 5 (18.75) | 2.6 (10) |

| Maximum Pressure (MAWP) | 1900 psi (131 bar) | |||

| Maximum Temperature | ||||

| with FKM O-ring | 225 °C | |||

| with FFKM O-ring | 300 °C | |||

| with PTFE Flat Gasket | 350 °C | |||

| Reactor Details | ||||

| Mounting Style | Moveable | Fixed Head | ||

| Stand Type | Table Floor Stand | Floor Stand | ||

| Closure | Split-Ring (12 Compression Bolts for Flat Gasket, no Compression Bolts for O-ring) | |||

| Valve Connections | 3/8″ Male NPT | |||

| Magnetic Drive, Model No. | A1750HC General Purpose or A2160HC Footless | |||

| Maximum Torque | 60 Inch-Pounds | |||

| Impeller(s), 6 blades | 2 (5.25″ dia.) | 2 (3.85″ dia.) | 2 (5.25″ dia.) | 2 (3.85″ dia.) |

| Stirrer Motor | 3/4 hp variable speed | |||

| Pressure Gage, Size | 4.5 inches | |||

| Range | 0-2000 psi (138 bar) | |||

| Temperature Measurement | Thermowell | |||

| Cooling Coil (optional) | Serpentine | |||

| Bottom Drain Valve (BDV) (optional) | 1.0″ NPT | |||

| Lift Mechanism (optional) | Manual Hoist | Pneumatic | ||

| Heater Style | Ceramic, 3-Zone | Band Heater, 3-Zone | Band Heater, 3-Zone | |

| Heater Power, Watts | 4500 | 4250 | 5500 | 3300 |

| Electrical Supply | ||||

| Volts, AC | 230-1P or 400-415V 3-Phase “Y” | |||

| Maximum Load, amps, 115 / 230 | 1P-30 amps, 3P-15 amps/leg | |||

| Cylinder Dimensions | ||||

| I.D. x Depth, inches | 9.5 x 16.3 | 7.75 x 12.2 | 9.5 x 16.3 | 7.75 x 12.2 |

| Vessel Assembly Weight, pounds | 354 | 206 | 355 | 209 |

| Cylinder Weight, pounds | 157 | 97 | 157 | 97 |

| Reactor/Stand Dimensions | ||||

| Width x Depth, inches w/o Controller | 63 x 25 | 31 x 43 | ||

| Height, inches | 91 | 95 | 87 | |

| Weight, pounds | 1000 | 900 | 1000 | 900 |

| Spare Parts Kit | 4559PCM | |||