תיאור

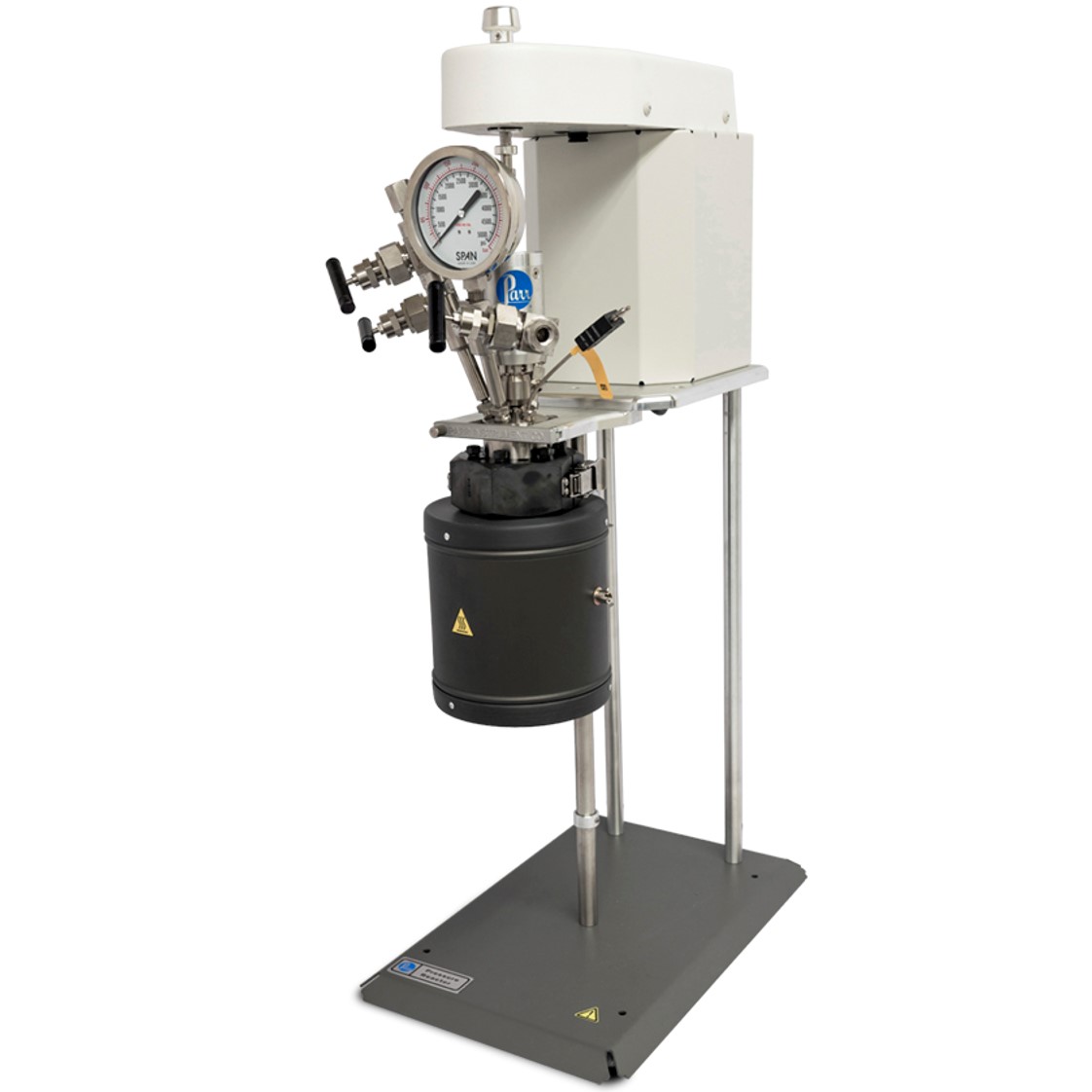

These are the smallest of all Parr Stirred Reactors. They will be a good choice for chemists working with very expensive materials or materials only available in small amounts. They will also appeal to users who wish to minimize the risks associated with hazardous materials or reactions by restricting the reactants or products to a minimum. Use of the Series 4590 Reactors also helps minimize the quantities of waste products which may require special disposal procedures. The 4590 systems are now available in high pressure (5000 psi) or high pressure/high temperature (500 °C) versions.

These micro reactors have been designed to provide as many of the features of the larger vessels as possible in the limited space available. All of the standard head fittings are provided, with optional cooling now available with aluminum block heaters with cooling capability, welded jackets or Cold Fingers.

These systems are offered in both fixed head and moveable head vessel styles with choices of a self sealing O-ring for temperatures up to 225 °C or with FFKM O-ring for temperatures to 275 °C or with a flat PTFE gasket for temperatures to 350 °C, or with a Flexible Graphite gasket for temperatures to 500 °C with the HP/HT option (for fixed head versions only). A split ring closure is standard.

All three volumes use the same ceramic fiber heater.

These micro reactors can be easily converted from one size to another by simply substituting a larger or smaller cylinder and the corresponding internal fittings. The support system can also be readily adapted to accept any of the vessels from the 4560 Mini Reactor Series. The opportunity to modify these small reactors is restricted because of the limited head space available.

| Series 4590 Pressure Reactor System Specifications | ||||||

| Shaded bar indicates specifications that change within series. | ||||||

| Model Number | 4591 | 4592 | 4593 | 4596 | 4597 | 4598 |

| Approximate Volume, mL | 25 | 50 | 100 | 25 | 50 | 100 |

| Maximum Pressure (MAWP) | 3000 psi (207 bar, 200 bar for CE orders) | |||||

| Maximum Pressure for HP, HP/HT (MAWP) | 5000 psi (345 bar) | |||||

| Maximum Temperature | ||||||

| with FKM O-ring | 225 °C | |||||

| with FFKM O-ring | 300 °C | |||||

| with PTFE Flat Gasket | 350 °C | |||||

| with Flexible Graphite Flat Gasket (HP/HT) | 500 °C | |||||

| Reactor Details | ||||||

| Mounting Style | Moveable | Fixed Head | ||||

| Stand Type | Bench Top | |||||

| Closure | Split-Ring (6 Compression Bolts for Flat Gasket, no Compression Bolts for O-ring) | |||||

| Valve Connections | 1/8″ NPT Male (1/4″ NPT Male for HP, 1/4″ NPT Female for HP/HT) | |||||

| Magnetic Drive, Model No. | A1120HC6 | |||||

| Maximum Torque | 16 Inch-Pounds | |||||

| Impeller(s), 4 blades | 1 (.81″ dia.) | |||||

| Stirrer Motor | 1/8 hp variable speed | |||||

| Pressure Gage, Size | 3.5 inches | |||||

| Range | 0-3000 psi (207 bar), 0-5000 psi (345 bar) HP, HP/HT | |||||

| Temperature Measurement | Fixed Thermocouple (Thermowell for special alloys) | |||||

| Cooling (optional) | Cold Finger | |||||

| Bottom Drain Valve (BDV) | N/A | |||||

| Heater Style | Ceramic Fiber Heater | |||||

| Heater Power, Watts | 700 | |||||

| Electrical Supply | ||||||

| Volts, AC | 115 / 230 | |||||

| Maximum Load, amps, 115 / 230 | 7/4 | 7/4 | ||||

| Maximum Load, amps, for HP/HT, 115 / 230 | N/A | 7/4 | ||||

| Cylinder Dimensions | ||||||

| I.D. x Depth, inches | 1.0 x 2.0 | 1.3 x 2.3 | 1.3 x 4.6 | 1.0 x 2.0 | 1.3 x 2.3 | 1.3 x 4.6 |

| Vessel Assembly Weight, pounds | 18 | 18 | 19 | 19 | 19 | 20 |

| Cylinder Weight, pounds | 3.5 | 3.1 | 4.2 | 3.5 | 3.1 | 4.2 |

| Reactor/Stand Dimensions | ||||||

| Width x Depth, inches w/o Controller | 12 x 18 | |||||

| Height, inches | 27 | 35 | 27 | 35 | ||

| Weight, pounds | 55 | 56 | 57 | |||

| Spare Parts Kit | 4599M (4599HPHT for High Temperature) | |||||

|

* Add 8″ to height for Aluminum Block Heater option. |

||||||

|

Other options available. See Ordering Guide or call for more information. |

||||||