תיאור

The ABT™ (Abel test) apparatus is used for the traditional determination of the thermal stability of firearm and rocket propellants by the measurement of the time interval needed to evolve nitrogen oxide gasses from the heated sample. Iodide Starch Indicator Papers are used for the detection of the presence of decomposition gases. The test temperature is typically set between 60 – 82°C. The nitrate esters decompose evolving nitrogen oxide gases which are detected by means of the standardized color change of the Iodide Starch Indicator Paper. The period of time between inserting the heating block with samples and the moment of the color change of the indicator paper is the test time. The typical sample mass is 1-3g and the measured temperature ranges between 60 – 82°C with a testing period up to 1 hour.

The ABT™ makes testing quick and easy. The moment the color change occurs on the indicator paper the test is complete.

APPLICATION

The ABT™ is designed especially for the thermal stability assessment of single-base and double-base firearm and rocket propellants in quality control and other industrial applications. Additionally, if desired, it can be used for other materials and mixtures containing nitrocellulose, nitroglycerine, or other organic nitrates.

The Abel test belongs to a group of methods based on the change of color of indicator papers along with the methyl violet test (MVT™), Heat test (CH100™) or the Vieille test. These tests differ from each other in terms of the measurement of temperature, weight of the sample, size and shape of the heating tubes or the kind of indicator paper used. They are well suited for comparing various batches of propellants–but not useful for comparing different types of compounds.

The ABT™ is uncomplicated and dependable-it is a natural choice for an independent complementary method to the vacuum stability test (STABIL VI®) or the high performance liquid chromatography apparatus (HPLC-OZM1220™).

DESCRIPTION

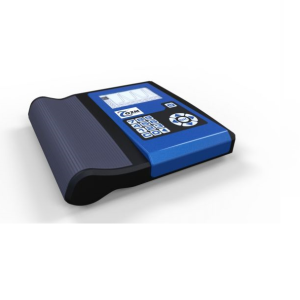

The ABT™ apparatus consists of a heavy, aluminum heating block made of with 10 test tube holder holes. Each tube is covered with an individual lid equipped with a small hook. The indicator paper is then hung conveniently on the hook which is placed inside the tube when the lid is secured. OZM Research® supplies the highest quality of indicator paper-guaranteed to meet US Navy specifications and is currently being utilized and accredited by the USA Military.

The glass test tubes (with the tested samples and indicator paper) are inserted into their holders in the heating block. The temperature of the block is administered by a control unit which is comprised of an operational controller and a limit controller. The limit controller operates an independent alarm circuit which halts the heating process if temperatures were to accidentally increase above specified safety limits. Calibrated mercury thermometers or calibrated digital thermometers may be used to correct and control the temperature of the heating block.

The ABT’s™ standard heavy, aluminum heating block can hold and measure up to 9 samples (with individual time exposures for each one). Heating blocks with a different desired number of holes are available on request.

ADVANTAGES & FEATURES

- Safer operation–the aluminum heating block is much safer compared to a traditional reflux heating bath

- Customized heating blocks available upon request

- High precision and accuracy of the heating block temperature

- Fast operation time and proven testing procedures

- Independent alarm circuit led by the limit controller eliminates prolonged accidental overheating