תיאור

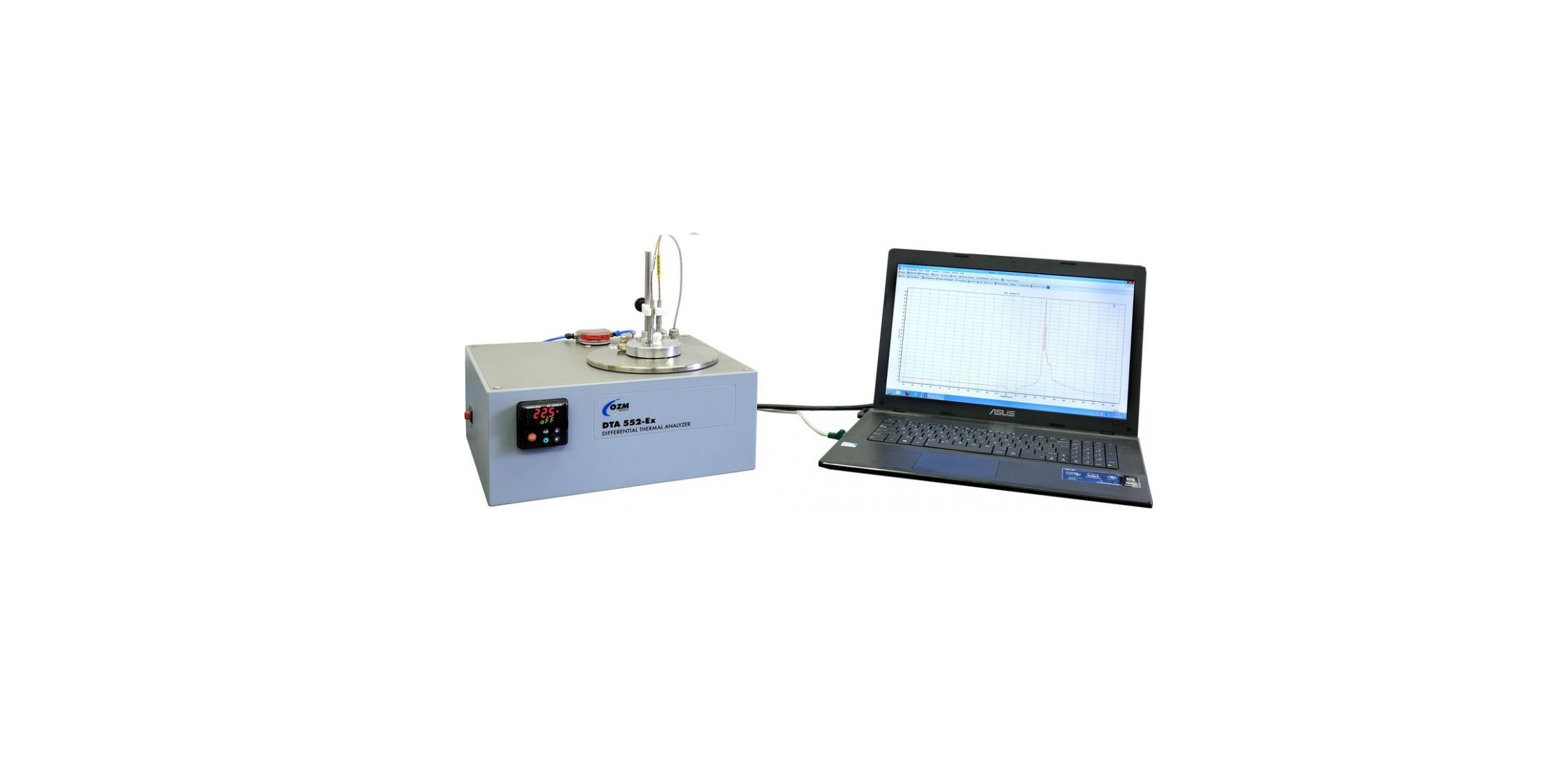

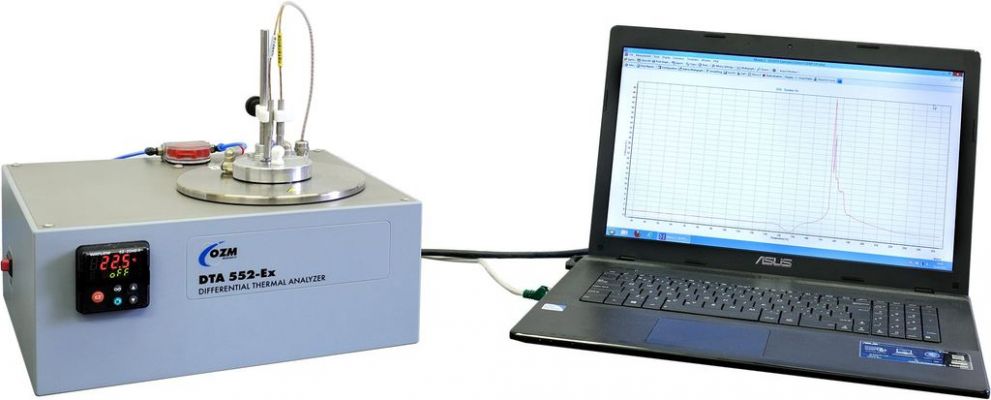

The DTA 552-EX™ (Differential Thermal Analyzer) was developed specifically for the evaluation of thermal stability, purity (melting point), compatibility and decomposition parameters of all types of energetic materials including primary explosives or other substances possessing a potential violent decomposition. The thermal behavior of the sample is observed during heating. The heating rate is constant. (Alternatively, an isothermal heating program is also available.)

Due to the DTA 552-EX’s™ sturdy design it is the ideal choice for the characterization of explosive materials which produce explosions likely to damage or destroy to less robust commercial analyzers. Not only strong but fast–the DTA 552-EX™ analysis, including data evaluation, takes only 1 to 2 hours. The typical sample mass is 30-50mg for high explosives and 10 mg for primary explosives and sample is heated by constant heating rate 5°C.min-1 up to maximal temperature 550 °C.

APPLICATION

The DTA 552-EX™ detects and analyzes thermal changes (melting, polymorph transformation, evaporation and thermal decomposition) occurring in the sample allowing for the evaluation of the thermal stability, purity, compatibility and the thermal decomposition parameters of all types of propellants and explosives.

The DTA 552-EX™ is an essential instrument for quality control of energetic materials or raw materials, characterization and qualification of new compounds, in-service surveillance, research & development or many other testing programs.

DESCRIPTION

The DTA 552-Ex™ instrument consists of a aluminum heating block with two test tube holder holes–one of the tested substance; the other the inert reference material. The heating block is surrounded by a stainless steel thermal jacket. The jacket is filled with water which allows for uniform testing conditions and automatic cooling after each test–enabling quick preparation for the next test. The temperature difference between the sample and the reference material is measured by a pair of sheathed, corrosion protected thermocouples inserted directly into the samples. A personal computer continuously records data; recording and evaluating it via MEAVY™ software for Windows 7. Heating is programmed into the temperature controller. An independent temperature sensor is used for control heating.

ADVANTAGES & FEATURES

- Robust design–able to withstand an explosion of up to several hundred milligrams of explosives

- Flexibility of tested substances (paste, liquid, foam and corrosive substances)

- High sensitivity–direct contact of one thermocouple with each sample

- Speedy operation and data evaluation

- High precision and accuracy

- Large variety of accessories

- User-friendly software for data acquisition, analysis and archiving

- Low cost investment and operation.