תיאור

Pressure and shearing action

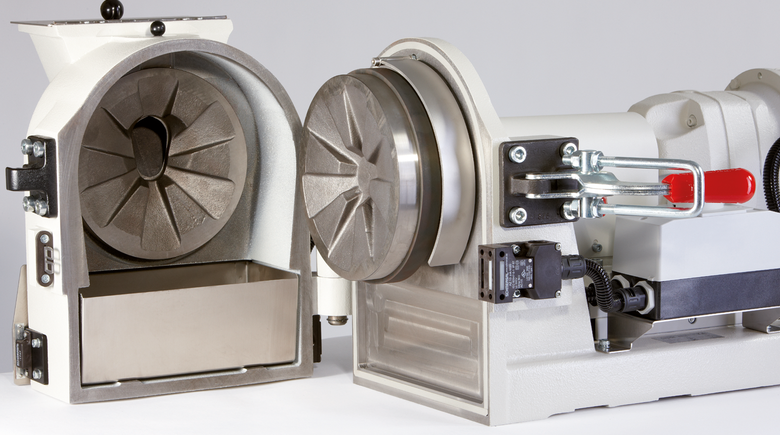

The material to be ground is comminuted by pressure and shearing action between two counteracting grinding disks with coarse interlocking teeth. The ground material automatically falls down through an output gap into the collection drawer. The desired final fineness can be defined from the outside by changing the gap width.

- Precise gap setting with an accuracy of 0.1 mm

- Fast, easy cleaning

- Simple operation

- Fast grinding disk change

- Precision setting of the final fineness even during grinding

- High service life due to generously dimensioned bearings

- Especially safe due to central tension lock of the grinding chamber

- Easy gap width check from the outside

- Combinable with the Jaw Crusher PULVERISETTE 1 classic line

Configure your Disk Mill PULVERISETTE 13 classic line exactly to your specific application

For every FRITSCH Disk Mill PULVERISETTE 13 classic line, you need at least one fixed and one movable grinding disk, which are available in various materials. Normally, two grinding disks of the same material are selected, which must always be harder than the sample to be ground. Grinding disks of zirconium oxide are only suitable for grinding ceramic materials, minerals, etc. and never for hard-tough samples, such as metals.

Metal-free grinding

For completely metal-free grinding of hard-brittle and medium-hard solid samples, for example for dental ceramics, we can equip your FRITSCH Disk Mill PULVERISETTE 13 classic line with a thorough polymer interior coating – together with grinding disks made of zirconium oxide – an absolutely reliable protection against iron contamination.

The powerful combination for pre- and fine-crushing in a single step

For fast, continuous pre- and fine-grinding particularly of large quantities of coarse material, the combination of the FRITSCH Disk Mill PULVERISETTE 13 classic line and the FRITSCH Jaw crusher PULVERISETTE 1 classic line is the ideal solution. Mounted together onto a rack and connected to each other by a chute, they automatically grind the material from a particle size of up to 95 mm to a final fineness of down to 100 μm – fast, easy and effective in a single step!

| Working principle | shearing |

| Optimal for material type | very hard, hard-abrasive, hard-brittle, medium-hard samples and for metal-free grinding |

| Grinding tools | fixed and movable grinding disk |

| Materials of the grinding tools | hardened steel cast, manganese steel, hardmetal tungsten carbide, zirconium oxide |

| Max. feed size (depending on the material) | 20 mm |

| Min. sample quantity | 20 – 30 ml |

| Max. throughput (depends on material) | 150 kg/h |

| Final fineness | 0.1 – 12 mm |

| Feeding | batchwise/ continuous |

| Rotating speed | grinding disk 440 rpm |

| Bearings | needle and double row angular contact ball bearings |

| Electrical Details*(other voltages on request) | 400 V/3~, 50 Hz, 1790 watt |

| Instrument also available in the following voltage (other voltages on request) | 200 V/3~, 60 Hz, 2100 watt order no. 13.1020.00 |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground) | approx. LpAd = 89 dB |

| Weight | 140 kg |

| Dimensions (W x D x H) | bench top instrument 44 x 87 x 40 cm |