תיאור

The Tackiness Tester

Our tackiness tester provides an efficient and reliable procedure for the determination of the tackiness. The GABOTACK® system allows reproducible measurements of surface adhesion (tackiness, autohesion) of either two identical or even different adhesive components.

It is designed for testing of various materials such as elastomers, polymers, epoxy resins, paints andlacquers, prepregs, adhesive tapes and pharmaceuticals.

Insufficiently product properties due to internally poor contactareas belong to the past.

Measurements with Know-How

- Absolute values of deformation, force, time and speed

- Determination of the peel force (“tack” force), necessaryto separate the segments

- Determination of the “tack” energy as the mechanicalwork used for separation of samples

- Variation of the following adjustable parameters:force of pressing, time of pressing, speed of pressing,speed of separation

- Storage of the raw data

- Changeable force transducers of 150 N or 500 N (option)

- Changeable sample holders (clamping devices) for“Green Tire” segments and epoxy systems are available(individually customized devices on request)

Key Technical Data

(subject to change)

Force range:

150 N or 500 N

Speed of pressing:

up to 3 mm/sec

Force of pressing:

up to 500 N

Time of pressing:

up to 1000 sec

Detectable peel force:

up to 500 N

Measuring Time:

20 min

Fields of Application

- Elastomers, for instants tires („Green Tires“)

- Epoxy resins

- Varnish/paint work

- Component segments

- Adhesive tapes

- Pharmaceuticals

- Polymers

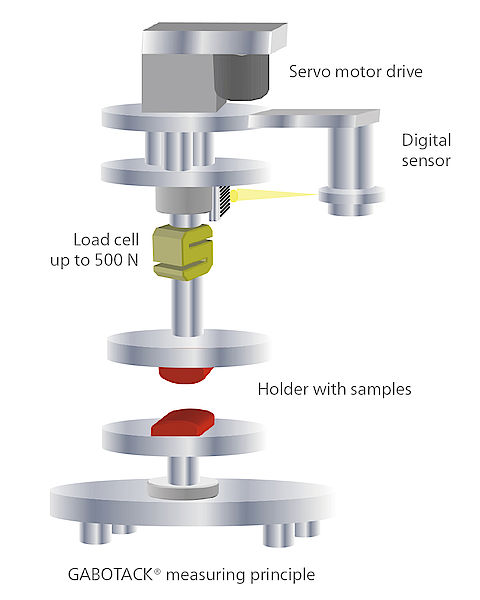

Measuring Principle

How does it work?

The “tack” force as well as the “tack” energy (optional) can be determined with the GABOTACK® system. “Tack” force and “tack”energy correspond to the required force and the required mechanical energy necessary to separate the defined surface of twoadhesive materials.

Segments of adhesive components are used as specimens. Square and rectangular shaped samples with a dimension up to 40 mm side length can be inserted, but also circular components are applicable. The material thickness is permitted within the range from 2 up to 30 mm.

Two test specimens have to be inserted (see measuring principleof the GABOTACK® system).

The GABOTACK® system immediately allows the reproducible and reliable measurement of the “tack” force with respect to the adjustment of relevant parameters (time of pressing, force of pressing, speed of pressing and speed of separation).