תיאור

Broadest temperature range available, from -100°C to 500°C

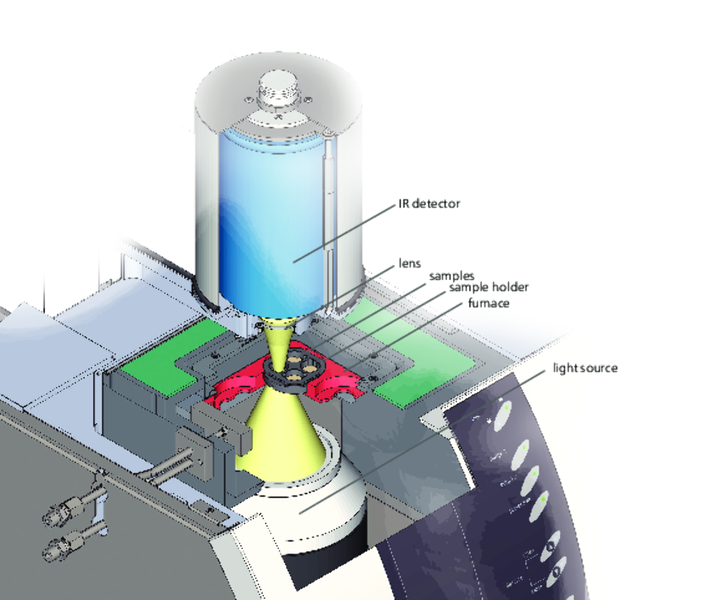

With a single instrument setup – that is, without having to swap out either the detector or the furnace – the LFA 467 HyperFlash® can carry out measurements from -100°C to 500°C. Coupled with the broadest range of accessories available on the market, the instrument opens the door to completely new dimensions in the determination of thermophysical properties.

Sample throughput up to 4 times higher due to sample holder for 16 samples

One unique advantage of the LFA 467 HyperFlash® is its ability to simultaneously measure up to 16 samples over the entire temperature range. This allows for maximum sample throughput with a minimum input of operational time and effort.

Refill systems are available for automatic refilling of the Dewar on both the detector and the furnace, allowing uninterrupted operation of the LFA system around the clock.

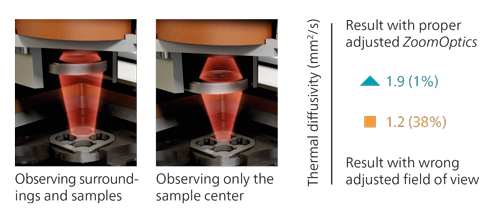

ZoomOptics for more precise measurement results without measurement errors

The patented ZoomOptics system (patent no.: DE 10 2012 106 955 B4 2014.04.03) optimizes the field of view of the detector, thus eliminating any influences caused by aperture stops. The result is a significant increase in the precision of the measurement results.

Ultra-fast recording of measurement data for thin samples (2 MHz)

Thin films and high-conductivity materials require a very high data acquisition rate for the precise recording of rapid temperature increases on a sample’s upper surface. The LFA 467 HyperFlash® offers a sampling rate of 2 MHz – an unprecedented value for LFA systems.

Key Technical Data

(subject to change)

-

Temperature range:

-100°C to 500°C,

with only one single furnace

- Contactless measurement of the temperature increase with IR detector

-

Data acquisition rate:

up to 2 MHz (for both thermal curve and pulse mapping)

-

Measuring range thermal diffusivity:

0.01 mm2/s to 2000 mm2/s

-

Measuring range thermal conductivity:

< 0.1 W/(m*K) to 4000 W/(m*K)

-

Sample dimensions:

- 6 mm to 25.4 mm diameter

- 0.01 mm to 6 mm thickness

-

Patented pulse mapping technique

for pulse length correction and improved cp determination

-

Compliant to and in accordance with:

ASTM E1461, ASTM E2585, DIN EN 821-2, DIN 30905, ISO 22007-4, ISO 18755, ISO 13826; DIN EN 1159-2, etc.

ZoomOptics

ZoomOptics for more Precise Measurement Results without Measurement Errors

Generally, the area on the sample’s upper surface being scanned by the detector is customized to fit to the maximum sample size up to 25.4 mm. Samples with a smaller diameter are most often covered with a mask or a cap to hide peripheral zones to the greatest extent possible. Since all bodies, however, emit infrared radiation – i.e., even the masking or capping material – the resulting detector signal is inevitably influenced. The extent to which this influence is noticeable depends on the difference in thermal diffusivity between the sample and the mask/cap material. The result – in the final segment of the main temperature rise – can be either a further continuous increase or a premature leveling of the detector signal. In either case, a shift of the evaluated half time occurs, thus falsifying the calculated thermal diffusivity.

ZoomOptics (patent no.: DE 10 2012 106 955 B4 2014.04.03) allows the detector’s field of view to be adjusted until the only temperature increase registered is that of the sample and no influences by the surroundings or mask can have any effect. The pre-set focus value – which covers most applications – is 70%; however, this value can also be individually adjusted by the operator to the given sample geometry.