תיאור

Main featuresH Fast Heating Reliable Sterilisation Rapid Cooling

|

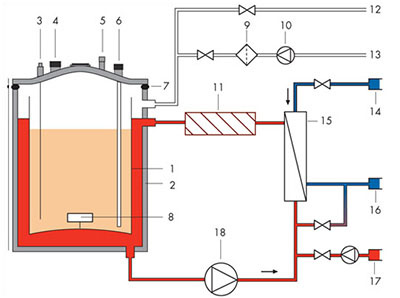

System block diagram1 MEDIACLAVE guarantees gentle and rapid sterilization of standard and highly sensitive culture media. Efficient heating, cooling and homogenous mixing minimize thermal stress and guarantee maximum medium fertility. |

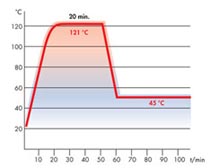

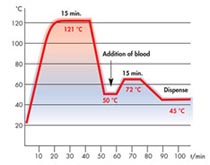

Operation modesM Culture medium can be suspended and dissolved directly within the MEDIACLAVE. The strong magnetic stirrer guarantees homogeneous mixing within the vessel and prevents coagulation. Alternatively, culture medium can be dissolved and pre-swelled using the WATER BATH operation mode prior to sterilization. The intuitive, multilingual graphical user interface makes it very easy for everyone to use MEDIACLAVE – no special training of the staff is required. Up to 50 programs with user-defined parameter settings such as sterilization temperature, sterilization time or dispensing temperature Operation modes: 1. STANDARD mode: For the preparation of standard and highly sensitive culture media. Sterilization temperature/time and dispensing temperature can be set. 2. CHOCOLATE AGAR mode: A special two-step program that allows the preparation of complex media. After the first sterilization phase, supplement, e.g. blood, can be added through the adding port. Subsequently, a second heating phase is performed. 3. WATER BATH mode: For pre-swelling culture media prior to sterilization within the temperature range 30 – 80 °C. In combination with an autoclave cuvette (only MEDIACLAVE 10), liquids in glassware can be thermostatted. 4. AUTOCLAVE mode (MEDIACLAVE 10 only): MEDIACLAVE 10 can be used as a benchtop autoclave to sterilize culture medium in glassware such as Erlenmeyer flasks or test tubes. Standard mode: Heating up, sterilization and cooling down to dispensing temperature.

Chocolate Agar mode: After the first sterilization phase, blood is added and the medium heated up again

|

DispensingThe wide adding port facilitates safe addition of supplements such as antibiotics or blood prior to dispensing. The automatic in-process sterilization of the dispense port minimizes the risk of medium contamination during dispensing. The vessel and the dispensing system of the MEDIACLAVE were designed to avoid dead volume and to have maximum medium yield. MEDIACLAVE can be quickly and conveniently connected to the dispensing tubing of the automated Petri dish filler MEDIAJET. Up to 540 Petri dishes can be filled with Agar medium at the touch of a button. Alternatively, the peristaltic pump DOSE IT can be used to fill containers of more unusual volumes or shapes, e.g. quadrangular Petri dishes, bottles or flasks.

|

Process documentation and validationMEDIACLA All logfiles can also be stored using the MEDIACLAVE USB port. I |

| Capacity | MEDIACLAVE 10 | MEDIACLAVE 30 |

| Stainless steel cuvette | 1 – 10 litres | 3 – 30 litres |

| Autoclave cuvette (Ø, H) | 254 mm, 203 mm | – |

| Temperature range | ||

| Sterilisation | 30 °C – 122 °C | 30 °C – 122 °C |

| Dispensing | 25 °C – 80 °C | 25 °C – 80 °C |

| Water bath | 30 °C – 80 °C | 30 °C – 80 °C |

| Max. temperature deviation | +1.0 °C/-0.2 °C | +1.0 °C/-0.2 °C |

| Time | ||

| Heating up (25 °C – 121 °C) | 20 – 60 min | 20 – 60 min |

| Sterilisation | 1 – 99 min | 1 – 99 min |

| Cooling down (121°C – 55°C) | 5 – 20 min | 5 – 30 min |

| Stirrer speed | ||

| Selectable | 50 – 200 rpm, reversing direction | 50 – 200 rpm, reversing direction |

| Utilities | ||

| Heating Capacity | Max. 3 kW | Max. 9 kW |

| Interfaces | 2 x RS232, Ethernet, USB port, | 2 x RS232, Ethernet, USB port |

| AUX contact, footswitch, | AUX contact, footswitch, | |

| ext. pinch valve | ext. pinch valve | |

| Cooling water connections | ¾” thread | ¾” thread |

| Graphic LCD-display | 240 x 128 points | 240 x 128 points |

| Electricity supply | ||

| All MEDIACLAVE 10 instruments | 200 – 240 V 50/60 Hz, 16 A | – |

| MEDIACLAVE 30, US/JP (136 050) | – | 200 – 208 V 3~/PE, 50/60 Hz, 30 A |

| MEDIACLAVE 30, EU (136 055) | – | 400 V 3~/N/PE, 50/60 Hz, 16 A |

| Dimensions and weight | ||

| Basic Device (H x W x D) | 480 mm x 550 mm x 640 mm | 1040 mm x 550 mm x 640 mm |

| Weight | 57 kg | 85 kg |

igh Operational Safety

igh Operational Safety and strong magnetic stirrer with adjustable speed and reversing rotation direction ensures homogenous media preparation over a wide viscosity range. A Pt-1000 temperature probe and microprocessor control of process parameters allow reproducible and complete sterilization of culture media.

and strong magnetic stirrer with adjustable speed and reversing rotation direction ensures homogenous media preparation over a wide viscosity range. A Pt-1000 temperature probe and microprocessor control of process parameters allow reproducible and complete sterilization of culture media. g is enabled by an efficient plate heat exchanger. The separation of the cooling water system and the sterilization chamber makes it unlikely that culture media gets contaminated by cooling water. The built-in support pressure system prevents a delay in boiling during the rapid cool down phase, allowing an extraordinary fast and gentle cooling.

g is enabled by an efficient plate heat exchanger. The separation of the cooling water system and the sterilization chamber makes it unlikely that culture media gets contaminated by cooling water. The built-in support pressure system prevents a delay in boiling during the rapid cool down phase, allowing an extraordinary fast and gentle cooling. Media cuvette

Media cuvette EDIACLAVE is quickly set up. Insert the cuvette (container for media), fill in the coupling water (water jacket between the cuvette and the vessel for efficient heat transfer) and you are ready to prepare your culture medium.

EDIACLAVE is quickly set up. Insert the cuvette (container for media), fill in the coupling water (water jacket between the cuvette and the vessel for efficient heat transfer) and you are ready to prepare your culture medium.

Large containers such as bottles can be filled by pressure dispensing. Medium is dispensed by automatically building up pressure inside the sterilization chamber. Requires optionally available Pressure Dispense Kit.

Large containers such as bottles can be filled by pressure dispensing. Medium is dispensed by automatically building up pressure inside the sterilization chamber. Requires optionally available Pressure Dispense Kit. VE supports individual needs in process documentation and validation. The sterilization process can be monitored and stored using a PC. A digital signature according to FDA (21 CFR Part 11) / EU (GMP Annex 11) is automatically added to the electronic process file.

VE supports individual needs in process documentation and validation. The sterilization process can be monitored and stored using a PC. A digital signature according to FDA (21 CFR Part 11) / EU (GMP Annex 11) is automatically added to the electronic process file. f equipped with an optionally available dot matrix printer, high quality printouts insusceptible to fading can be archived. To minimize paper consumption, the printout intervals can be increased

f equipped with an optionally available dot matrix printer, high quality printouts insusceptible to fading can be archived. To minimize paper consumption, the printout intervals can be increased