תיאור

Main features

|

Easy handling

|

|

Reliable walk-away automation W |

|

Media cost reduction

MEDIAJET has a built-in "Agar Spread Function" which ensures a homogenous distribution and an even surface of the agar. It helps to optimize the Agar level in the Petri dish and thereby allows a significant reduction of media costs. |

|

Eli For consistent Agar plate quality, a clean environment is essential. The surface of the filling chamber is manufactured of a single piece of resistant PE, which allows efficient cleaning. In addition, MEDIAJET is equipped with a UV lamp extending over the full length of the rotor where the dishes are opened during the filling process. The lamp emits powerful 2.1 W UV-C radiation for optimal bactericidal activity in the area most vulnerable to contamination. |

Operation ModesU Different operation modes for Petri dish filling can be executed and the parameters set to your needs: 1. STANDARD mode: Used for filling of Ø 90, 60 or 35 mm Petri dishes. 2. TURBO mode: Used to accelerate the filling process. Together with the optional Turbo Mode Kit installed, up to 1'100 Petri dishes can be filled in one hour. 3. BATCH mode: The Batch mode is used for applications where a highly planar agar surface is important, as for example in automatic colony counting. 4. POUR PLATE mode: Total viable count determination is mainly carried out by using the pour plate method. The POUR PLATE mode facilitates this process by automatically shaking the Petri dishes. Different shaking levels are selectable according to requirements.

|

Process documentation and validationMEDI In connection with MEDIACLAVE, these data can also be printed on its embedded printer. If connected to MEDIACLAVE 10 or MEDIACLAVE 30, an electronic log file including the MEDIAJET process data is created. |

Petri dish imprinting

ety of information onto the Petri dishes like alphanumeric text, expiry/production date or barcodes.

|

MEDIAJET vario allows the filling of Ø 90, Ø 60 or Ø 35 mm dishes by using the corresponding conversion set.

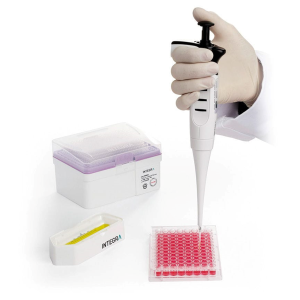

MEDIAJET allows Blood Agar preparation – aloows the control of the INTEGRA peristaltic pump DOSE IT. This accessory is especially useful to continuously mix additives in the concentration of 3 – 10 % into the medium.

| MEDIAJET | Power supply | |||

| Dosing range per dish |

1 – 99.9 ml | Consumption | 200 W | |

| Dosing reproducibility | circa 1 % (at 15 ml) | Input voltage | 100 – 240 V 50/60 Hz | |

| Maximal dosing rate | 500 ml/min | Fuses | T 2A (2x) | |

| Filling delay | 0 – 9.9 sec | |||

| Capacity / Carousel | 540 (90 mm Petri dish) | Dimensions |

||

| 360 (90, 60, 35 mm Petri dish) | Basic unit (H x W x D) | 330 x 655 x 634 mm | ||

| Height with 360 Carrousel | 1070 mm | |||

| Height with 540 Carrousel | 1405 mm | |||

| Filling rates | Net weight | |||

| Standard filling rate | circa 900 dishes/hour (up to 15 ml) | Basic unit | 47.0 kg | |

| Turbo filling rate | circa 1'100 dishes/hour (up to 24 ml) | 360 Carrousel | 6.8 kg | |

| 540 Carrousel | 8.3 kg | |||

| Petri dish | ||||

| Dish diameter |

90 mm | UV-Lamp |

11 W (2.1 W UV-C, 253.7 nm) |

|

| 90, 60, 35 mm (vario) | ||||

| Dish height | 12 – 25 mm | |||

| Interface | 2 x RS232, Alarm, Inkjet, Foot switch |

|||

| TUBEFILLER | ||||

| Test tube diameters | 13, 16, 20, 25 or 30 mm | |||

| Dosing range | 0.5 – 999 ml | |||

| Flow rate | up to 260 ml/min | |||

| Test tube length | up to 25 cm | |||

| Dosing reproducibility | <1 % (at 1 – 99 ml) | |||

| Filling rate | 1000 tubes/hour (at 10 ml, 4 mm ID tubing) |

|||

The intuitive user interface makes it very easy to control all functions of MEDIAJET. The operation of the system is entirely self-explanatory, as all functions and prompts are explained in plaintext.

The intuitive user interface makes it very easy to control all functions of MEDIAJET. The operation of the system is entirely self-explanatory, as all functions and prompts are explained in plaintext. ith the novel Feed-In/ Stack-Out technology, MEDIAJET guarantees a reliable operation. Typical production variations in the diameter or shape of the Petri dishes are easily handled by the unit, as they are actively guided throughout the entire filling process. The optical dish sensors of MEDIAJET can be easily adjusted to virtually every Petri dish brand at the user interface level.

ith the novel Feed-In/ Stack-Out technology, MEDIAJET guarantees a reliable operation. Typical production variations in the diameter or shape of the Petri dishes are easily handled by the unit, as they are actively guided throughout the entire filling process. The optical dish sensors of MEDIAJET can be easily adjusted to virtually every Petri dish brand at the user interface level.

minating sources of contamination

minating sources of contamination

AJET provides all features necessary to support the individual needs in quality control. All process relevant information can be documented using a standard external printer or by directly transferring the information to a personal computer.

AJET provides all features necessary to support the individual needs in quality control. All process relevant information can be documented using a standard external printer or by directly transferring the information to a personal computer. Different optionally available inkjet printer connection kits allow the connection of three different brands of inkjet printers (MARKEM-

Different optionally available inkjet printer connection kits allow the connection of three different brands of inkjet printers (MARKEM- All supported inkjet printers allow side wall imprinting. Alternatively, dishes can be imprinted on the bottom using the LINX 5900 (4900) inkjet printer module.

All supported inkjet printers allow side wall imprinting. Alternatively, dishes can be imprinted on the bottom using the LINX 5900 (4900) inkjet printer module.