תיאור

Gentle fine grinding

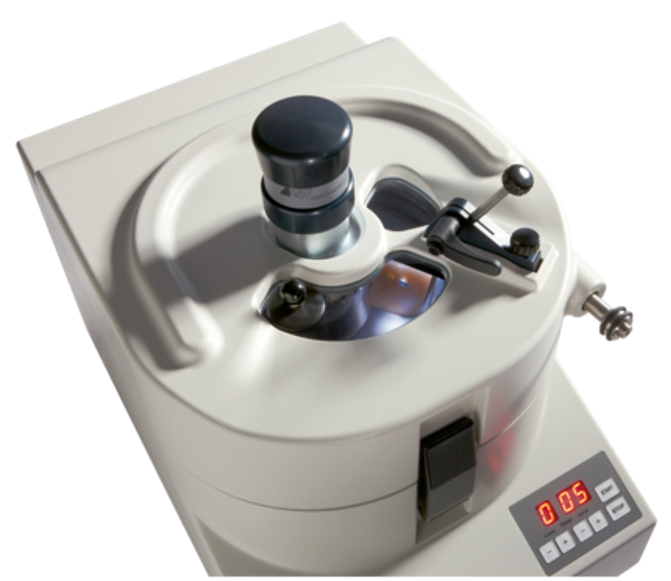

The principle of the Mortar Grinder is the oldest grinding principle in the world: using pressure and friction, the pestle, with its large grinding sur face, grinds the material against the walls and bottom of the mortar bowl. Your advantage: a particularly uniform and gentle grinding through friction, mixing or homogenisation of organic and inorganic samples with no thermal load – dry or in suspension at 70 to 80 rpm.

- For hard, medium-hard, soft, brittle, fibrous and abrasive materials

- Particularly gentle grinding with no thermal load

- Precisely adjustable pestle pressure and optimum scraper kinematics

- Loss-free grinding thanks to closed grinding chamber

- Illuminated grinding chamber for optimum control

- Simple filling even during grinding

- Easy cleaning through simple removal of pestle and mortar bowl

- Cryogenic grinding

- Automatic timer for reproducible grinding times

FRITSCH ADVANTAGE

The PULVERISETTE 2 is ideally suited for cryogenic grinding, where the material to be ground is embrittled with the addition of liquid nitrogen. In this manner moist, fibrous or elastic samples such as tomatoes, rubber, synthetic resins or plants can be ground without problem in the stainless steel grinding set.

Configure your Mortar Grinder PULVERISETTE 2 exactly to your specific application

Only available from FRITSCH: the mortar bowls of the PULVERISETTE 2 are rimmed regardless of the material, in a robust shell of shock-resistant plastic, which protects the actual bowl. This makes it particularly durable and the integrated all around grip ensures optimum working conditions. All FRITSCH mortar bowls have an extra high rim and are sealed by a sealing lip in the lid.

For contamination-free sample grinding, select the grinding set of your PULVERISETTE 2 from seven different materials – the appropriate pestle and scraper are also supplied. A grinding set made of stainless steel without a plastic frame is available, especially for cryogenic grinding using liquid nitrogen to embrittle the material to be ground. It is also heat-resistant and can be cleaned with solvents.

| Working principle | friction |

| Optimal for material type | hard, medium-hard, soft, brittle fibrous, abrasive and temperature sensitive |

| Grinding tools | mortar bowl with pestle |

| Materials of the grinding tools | agate, sintered corundum, hard porcelain, zirconium oxide, stainless steel, hardened steel, hardmetal tungsten carbide |

| Grinding bowl diameter | inner – 130 mm, outer – 200 mm |

| Max. feed size | 8 mm |

| Min. sample quantity | 10 ml |

| Max. sample quantitiy | Up to 190 ml |

| Final fineness | 10 – 20 µm |

| Grinding process | Dry/wet |

| Mortar bowl speed | 50 Hz – ~70 rpm, 60 Hz – ~80 rpm |

| Electrical Details (voltage indicated by customer is set) | 100-120/200-240 V/1~, 50/60 Hz, 300 Watt |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground and grinding set) | Approx. LpAd = 71 dB |

| Weight | 24 kg |

| Dimensions (W x D x H) | bench top instrument 31 x 46 x 41 cm |