תיאור

Comminution according to the Planetary Principle

The comminution of the material to be ground takes place primarily through the high-energy impact of grinding balls. To achieve this, the grinding bowl, containing the material to be ground and grinding balls, rotates around its own axis on a main disk whilst rotating rapidly in the opposite direction. At a certain speed, the centrifugal force causes the ground sample material and grinding balls to separate from the inner wall of the grinding bowl. The grinding balls then cross the bowl at high speed and further grind the sample material by impact against the opposite bowl wall. In addition, impact between the balls themselves on the sample material adds to the size reduction process.

The comminution of the material to be ground takes place primarily through the high-energy impact of grinding balls. To achieve this, the grinding bowl, containing the material to be ground and grinding balls, rotates around its own axis on a main disk whilst rotating rapidly in the opposite direction. At a certain speed, the centrifugal force causes the ground sample material and grinding balls to separate from the inner wall of the grinding bowl. The grinding balls then cross the bowl at high speed and further grind the sample material by impact against the opposite bowl wall. In addition, impact between the balls themselves on the sample material adds to the size reduction process.

Due to the enormous rotational speed of the main disk – up to 650 rpm – achieves the PULVERISETTE 6 classic line a centrifugal acceleration of up to 29 g.

- Special grinding force due to a rotational speed of up to 650 rpm

- Low space requirements and ergonomic design

- Particularly easy-to-use

- Timer programming precise to ± one second

- Simultaneous processing of up to 2 samples

- Useful capacity up to 225 ml

- Large rotational speed range with accurate display

- Easy to open grinding chamber completely encapsulated

- Cooling of the grinding chamber with a built-in fan for long grinding times

- Exactly reproducible grinding results thanks to a regulated drive, precise transmission ratio (toothed belt), programmable microprocessor control electronic

- Programmable interval and pause times

- Smaller grinding bowls also possible with an adapter

- RS232 interface for outputting process data (validation)

- Monitoring of the grinding parameters even when grinding chamber is open through an ergonomically positioned and always visible, splash-proof IP65 membrane keyboard

- Easy cleaning of the grinding elements

- Energy-save-function (electricity-saving mode)

- Extensive accessories for simplifying your daily work

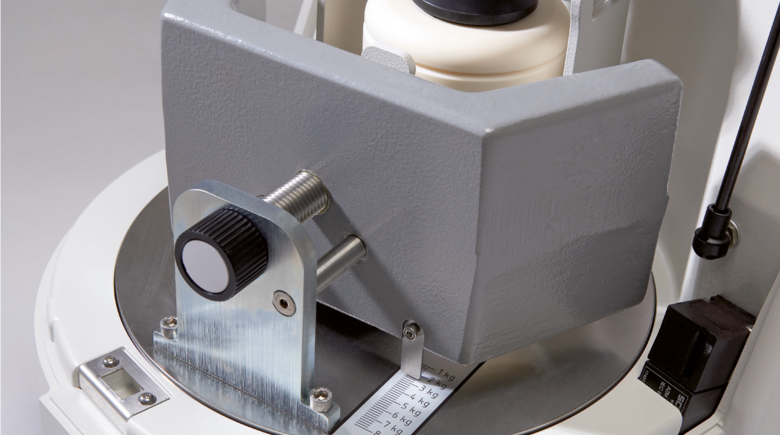

Reproducible grinding results and absolutely safe grinding bowl clamping

Especially convenient for exact, reproducibility and grinding of smallest sample amounts is the electronic timer: adjustable to the second and a programmable reversing feature. The Safe-Lock System, which is delivered with a torque wrench, enables simple and safe clamping of the grinding bowls – absolutely risk-free.

GTM – Gas Pressure and Temperature Measuring System

The Planetary Mono Mill PULVERISETTE 6 classic line can be combined with the GTM-System for measuring of the gas pressure and temperature during grinding. This turns your mill into an analytical measuring system.

Configure your Planetary Mono Mill PULVERISETTE 6 classic line exactly to your specific application

The Planetary Mono Mill PULVERISETTE 6 classic line with 1 working station operates with 1 respectively 2 grinding bowls of sizes 80, 250, 500 ml, which turn with a transmission ratio 1 : -1,82 relative to the main disk. To achieve best grinding results and for direct prevention of contamination of the samples due to undesired abrasion, grinding bowls and grinding balls are available in 6 different materials.

For grinding in inert gas, for mechanical activation and alloying are gassing lids recommended.

| Working principle | impact force |

| Optimal for material type | hard, medium-hard, soft, brittle, tough, moist |

| Number of working stations | 1 |

| Grinding tools | grinding bowls and grinding balls |

| Materials of the grinding tools | agate, sintered corundum, silicon nitride, zirconium oxide, hardened stainless steel, hardmetal tungsten carbide |

| Grinding bowl sizes | 80, 250, 500 ml |

| Grinding ball diameter | 0.1 – 40 mm |

| Max. feed size (depends on material) | 10 mm |

| Min. sample quantity | 10 ml |

| Max. sample quantity | 225 ml |

| Final fineness (depends on material) | < 1 µm |

| Typical grinding time down to analytical fineness | 4 min |

| Grinding process | dry/wet |

| Grinding in inert gas | yes |

| Gas pressure and temperature measurement | yes |

| Rotational speed of main disk | 100-650 rpm |

| Transmission ratio planetary disk / grinding bowl | i relative = 1 : -1.82 |

| Effective diameter of main disk | 121.6 mm |

| Centrifugal acceleration (g = 9.81 m/s²) | 29 g |

| Interfaces | yes |

| Electrical details | 100-120/200-240 V/1~, 50-60 Hz, 1000 Watt voltage, indicated by customer is set |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground, grinding bowls/balls, selected rotational speed) | up to approx. LpAd = 83 dB |

| Weight | 63 kg |

| Dimensions (W x D x H) | bench top instrument 37 x 53 x 50 cm |