תיאור

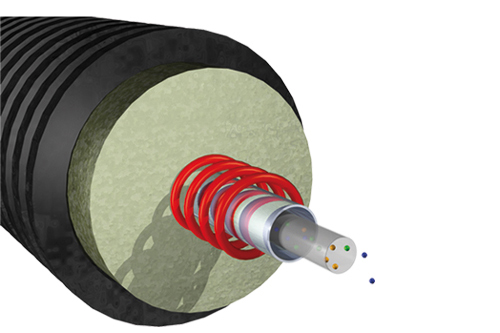

Capillary Coupling for Optimized Gas Flow Conditions

- Single-step pressure reduction

- Minimization of cold spots in the entire transfer path of the gases due to an even temperature of 300°C (optionally 350°C)

- Heated chamber for easy handling and precise adjustment of the quartz glass capillary inlet to the QMS

- Flexible, allowing standard thermoanalytical measurements and also simultaneous TGA, MS (GC-MS) and MS-FT-IR measurements

- Very robust and service-friendly while still maintaining high sensitivity (detectable mass loss in the μg-range)

- TGA-MS measurements under humid atmospheres possible

- Hyperbolic quadrupole system with pre-filter for improved transmission in the high mass range and improved sensitivity in the low mass range (e.g., H2, He)

- SEM with discrete dynodes and integrated Faraday cup for high dynamic range and long lifetime

- 3-D presentation of MS and thermal analysis data

- Operation and data evaluation with Proteus® software

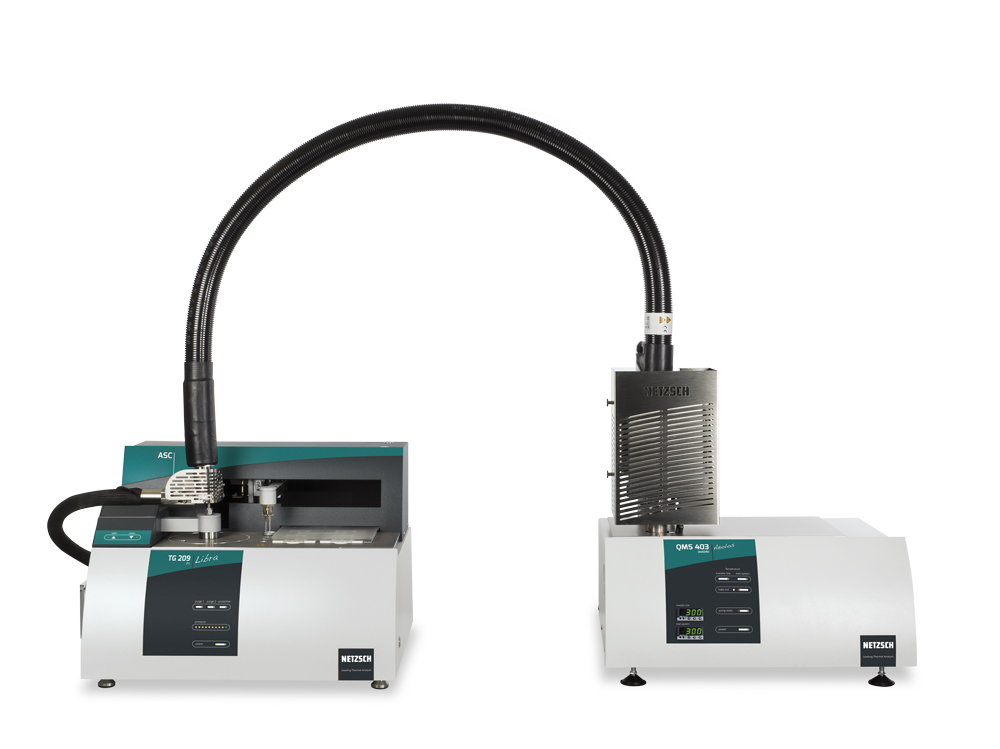

Sophisticated Heated Transfer System and Single-Step Pressure Reduction for Loss-Free Gas Transport

The high temperature of the gas transfer system and the absence of pressure reduction orifices practically eliminate condensation of decomposition products during thermal analysis experiments. This achieves a high detection sensitivity and facilitates quantitative detection of all identified gas components.

The inlet system with the capillary allows for the investigation of other gas sources independent of the thermoanalytical system.

Design of the NETZSCH Thermal Analyzers

Already from the outset, NETZSCH thermal analysis devices were developed with the possibility of coupling in mind. Over the last 40 years, the gas transport path – which starts at the furnace outlet and progresses via the adapter and capillary up to the QMS inlet – has been considered and optimized at every new phase in development. Today, any gas loss caused by condensation at cold spots has nearly been eliminated; also, very low carrier gas flow rates are sufficient for complete transfer. The minimal dilution of the volatile sample products released results in high detection sensitivity with the TGA/STA/DIL-QMS 403 Aëolos®Quadro.

Application Areas of the QMS 403 Aëolos® Quadro Coupling

-

Decomposition

- Dehydration

- Stability

- Residual

- Solvent Pyrolysis

-

Solid-Gas Reactions

- Combustion

- Oxidation

- Corrosion

- Adsorption

- Desorption

- Catalysis

-

Composition Analysis

- Polymer Content

- Proximate Analysis

- Binder Burn-Out

- Dewaxing

- Ash Content

-

Evaporation

- Vapor Pressure

- Sublimation

Key Technical Specifications

(subject to change)

-

Mass range:

1 u to 300 u(*), optionally 512 u, including autotuning

-

Ion source:

Cross beam El

-

Cathodes/Filaments:

2 Y2O3-coated iridium cathodes

-

Detector:

sem with discrete dynodes and integrated Faraday cup

-

Vacuum system:

turbomolecular pumps with 4-stage diaphragm pump (oil-free)

-

Capillary:

Quartz-glass (max. 300°C), optionally stainless steel (max. 350°C), with supply coil, easily exchangable

-

Adjustable heating of adapter head:

Capillary and QMS inlet system to a maximum of 300°C (optionally 350°C)

-

Pressure reduction:

Single-step, from 10³ mbar to 5×10-6 mbar, no orifice

-

QMS measuring modes:

Scan analog, scan bargraph, MID

A Single Software Program – Proteus Fully Controls Thermal Analyzer and QMS 403 Aëolos Quadro

Proteus® software entirely controls measurements using QMS 403 Aëolos® Quadro coupled to a thermal analyzer. The software combines the two coupled methods into a single software application for both control and data acquisition.

- Individual definition of any parameters relevant to thermal analysis (e.g., temperature program, heating rate, etc.) as well as any parameters relevant to the mass spectrometer (e.g., mass ranges, scans, etc.)

- Simultaneous start and stop of the hyphenated measurement

- Evaluation of MS results in Proteus®

- 3-D presentation of spectra data together with temperature, TGA and/or DSC curves and single mass number traces, including peak determination, different color schemes, and surface views

- Spectra export in NIST format for identification in the NIST database