תיאור

Key Technical Data

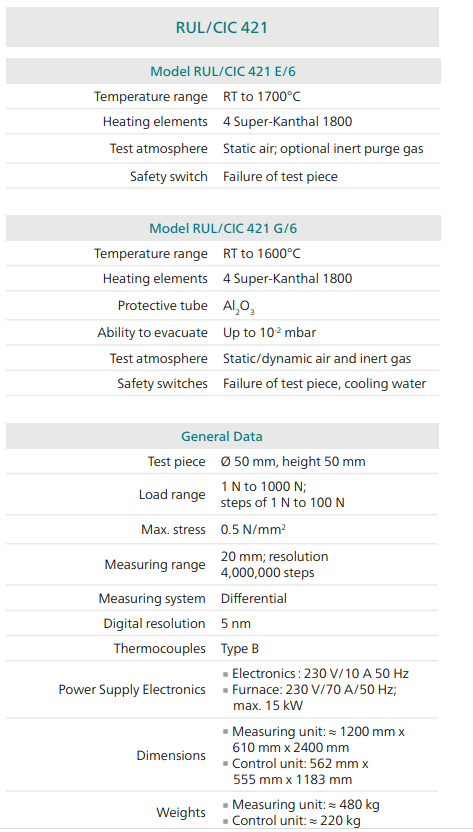

| Heating- and cooling rates: 0,01 K/min to 5 K/min |

Heating elements: 4 Kanthal-Super 1800 |

Temperature range: RT to 1700°C |

| Measuring range: 20000 µm |

Load: 1 N to 1000 N (in steps from 1 N to 100 N) |

Sample holder: Al2O3 |

| Sample length: 50 mm |

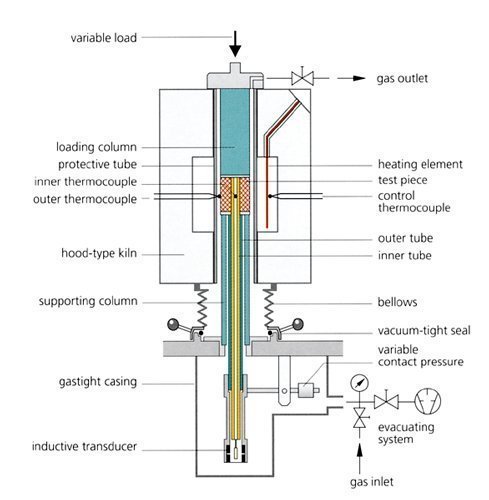

Temperature measurement: thermocouples (inner- and external temperature) |

Δl resolution: 5 nm |

| Vacuumtight version up to 10-2 mbar (special construction RUL/CIC 421 G) |

Atmospheres: air, static (protective gas inlet optionally available) |

Sample diameter: 50 mm |

Creep in compression (CIC, according to ISO 3187) refers to the percent of shrinkage of a refractory test piece under a constant load and exposed to a constant high temperature over a long period of time. The creep in compression test is also carried out in the RUL 421 to a maximum temperature of 1700°C. With its sturdy design, the RUL 421 is well suited for these long-running thermal and mechanical loads.

The same test-piece dimensions of 50 mm in diameter and 50 mm in height are used for both the RUL and the CIC tests. For the high-precision differential measuring system for determination of the deformation, the cylindrical test piece has a co-axial bore of 12.5 mm.

Selection and application of the load on the test piece are reproducible and independent of the deformation through use of the hood-type furnace with counterweights.

By reducing the load on the test piece to negligible values (as compared to the surface of the test piece), precise dilatometer measurements on large and even inhomogeneous samples can be carried out in the RUL 421 at temperatures up to 1700°C.

Software

The RUL/CIC 421 runs under Proteus® Software on Windows®. The Proteus® Software includes everything you need to carry out a measurement and evaluate the resulting data. Through the combination of easy-to-understand menus and automated routines, a tool has been created that is extremely user-friendly and, at the same time, allows sophisticated analysis. The Proteus® Software is licensed with the instrument and can of course be installed on other computer systems.

RUL/CIC analysis features:

- Plotting of the absolute or relative expansion/shrinkage curves

- Various correction options:

1. correction of the system’s own expansion behavior with either a calibration measurement or sample holder correction

2. offset correction - Semi-automatic routines for determination of onset, peak and end temperatures

- Determination of softening points in accordance with DIN/ISO standards

- Automatic softening point detection

- Derivation of curves for determination of the temperature- or time-dependent linear expansion rates

- Expansion coefficients: calculation and graphic presentation of the technical and physical expansion coefficients

- Specific graphics and tabulated results for RUL and CIC