תיאור

Despite these increased safety requirements, the RUMED® Safety X-Line offers almost the same equipment possibilities as the Safety T-Line.

Units of the X-Line can be installed in zone 1 and zone 2. This is possible due to a multitude of different types of protection (pressure-proof housing, intrinsic safety, increased safety, encapsulation).

All appliances of the X-Line have successfully passed a demanding type examination according to annex III of the ATEX 2014/34/EU allowing an application in zone 1 and zone 2. Yearly inspections (conformity of the type, annex VI of the ATEX 2014/34/EU) by a notified authority ensure the high quality and safety requirements.

The units are suitable for storage and tests of material of the temperature classes T1, T2 and T3 of explosion group IIA and IIB.

General view of the most important advantages:

- Entire system II 2G Ex IIB T3

- Approved for installation in the ex area zone 1

- 5 Test room sizes: 320 l to 1.640 l

- Test room and external housing of solvent-resistant stainless steel

- Recirculating air fan for good temperature distribution in space

- Easy handling by means of a precise temperature controller with digital display

- Temperature ranges from -20 °C to +80 °C

- Optional dehumidification and humidification

- Possibility of calibration and validation

- Robust and extremely durable

Technical Data

| Type | X 320 | X 500 | X 820 | X 1000 | X 1640 |

|---|---|---|---|---|---|

| Entire unit explosion-proof II 2 G Ex IIB T3 | |||||

| Volume (l) | 320 | 500 | 820 | 1000 | 1640 |

| Minimum temperature | 0 °C | 0 °C | 0 °C | 0 °C | 0 °C |

| Maximum temperature | +35 °C | +35 °C | +35 °C | +35 °C | +35 °C |

| Temperature deviation in time ( °C) | ±0,5 °C | ±0,5 °C | ±0,5 °C | ±0,5 °C | ±0,5 °C |

| Height (mm) | 990 | 1500 | 1500 | 1500 | 1500 |

| Width (mm) | 610 | 610 | 610 | 2 x 610 | 2 x 610 |

| Depth (mm) | 585 | 585 | 935 | 585 | 935 |

| Number of shelves (standard delivery scope) | 3 | 4 | 4 | 8 | 8 |

| Maximum load per shelf (kg) | 25 | 25 | 25 | 25 | 25 |

| Unit | |||||

| Height (mm) | 1600 | 2105 | 2105 | 2105 | 2105 |

| Width (mm) | 760 | 760 | 760 | 1520 | 1520 |

| Depth (mm) | 900 | 900 | 1250 | 900 | 1250 |

| Electric connection (V/Hz) | 400/230/50 | 400/230/50 | 400/230/50 | 400/230/50 | 400/230/50 |

| Options | |||||

| Additional shelf | X0320-01 | X0500-01 | X0820-01 | X1000-01 | X1640-01 |

| Additional shelf, reinforced (maximum load per shelf 50 kg) | X0320-02 | X0500-02 | X0820-02 | X1000-02 | X1640-02 |

| Glazed panel door, no pane heating | X0320-03 | X0500-03 | X0820-03 | X1000-03 | X1640-03 |

| Extension of temperature range down to -20 °C | X0320-04 | X0500-04 | X0820-04 | X1000-04 | X1640-04 |

| Extension of temperature range up to +80 °C* | – | X0500-05 | X0820-05 | X1000-05 | X1640-05 |

| Speed rate in temperature change 1 °C/min (0 °C to +35 °C) | X0320-06 | X0500-06 | X0820-06 | X1000-06 | X1640-06 |

| Speed rate in temperature change 1 °C/min (-20 °C to +80 °C) | X0320-07 | X0500-07 | X0820-07 | X1000-07 | X1640-07 |

| Humidification by evaporative humidifier + dehumidification | X0320-20 | X0500-20 | X0820-20 | X1000-20 | X1640-20 |

Options

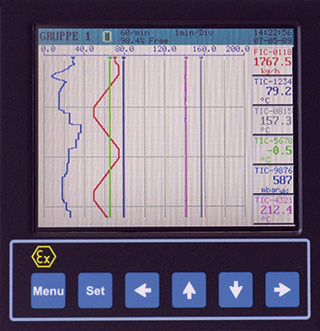

Digital recorderThe digital recorder of the X-Line is working without any paper, and it can be equipped with a digital interface, just like the controller. Due to corresponding transmitters, recording and control can be executed in areas being not explosion-proof. |

|

Tubular portA 45 mm duct in the side panel allows insertion of measuring lines and hoses into the test room. Delivery including cover. |

|

Closing plugGas-tight closing plug, matching to the tubular port. The gasket system with a flexibility in the range of 4 mm to 23 mm is based on a rubber module with removable skins and can be adapted to the cables, tubes etc. in different sizes. Order No.: X9930-02 |

|

Steering rollersMobile version of the test cabinet with 4 steering rollers, 2 of them lock-type with brake. |

|

Technical ventilation

If an evaporation of solvents cannot be avoided by procedural means, a technical ventilation is compulsory. The ventilation prevents the formation of a permanent explosive atmosphere (zone 0). Its efficiency is supervised redundantly by two flow switches. Depending on the density, the gases will be exhausted out of the unit either at ceiling level or at floor level. The air supply is effected vice-versa, at floor level or at ceiling level, to ensure, that the air flow covers all areas of the room. The fan ensures a high ventilation rate.

Order No.: X9980-01

Humidification

Equipped with the options humidification and dehumidification, an explosion-proof cold-heat test cabinet becomes an explosion-proof climatic test cabinet. Humidification of the Safety T-Line is effected by a specially controlled ultrasonic atomizer. Humidification of the Safety X-Line is realized by an explosion-proof version of evaporation humidification being installed in the test room. A plate heat-exchanger of stainless steel, which is optimized for this application, effects a dehumidification by falling below dewpoint. This combination of humidification and dehumidification allows a wide range of temperature/humidity combinations. The sensor is a temperature-compensated, capacitive sensor, which can be calibrated.