תיאור

The STABIL VI® (Modernized Vacuum Stability Tester, VST) is used for the determination of the chemical stability and compatibility of energetic materials specifically for firearm and rocket propellants. Electronic pressure transducers allow for the determination of the volume of evolved gases. More than 40 years ago the first electronic VSTs were developed in the former Czechoslovakia and now OZM Research™ is proud to present the sixth generation–equipped with an automatic measurement and evaluation system with uniquely designed test tubes and pressure transducer connections (previous instruments relied on mercury manometer tubes).

Electronic pressure transducers allow for the accurate recording of gas pressure which corresponds to the evolved gas volume of gases generated by decomposition, evaporation or sublimation. The typical sample mass is 5g and the measured temperature ranges between 90 – 120 °C with a testing period between 40 – 48 hours. The STABIL VI® trusted design ensures reliable and accurate results.

APPLICATION

The STABIL VI® is ideal for the determination of the thermal stability and compatibility (reactivity) of a wide range of propellants and other energetic materials (except primary explosives or materials with violent decomposition). The STABIL VI®– with precision and reproducibility–detects the presence of destabilizing impurities, determines the compatibility/incompatibility of surrounding materials and the effects of aging on energetic materials – all of which cause thermal or chemical instability.

The STABIL VI® testing capabilities are diverse spanning from quality control, to hazardous materials, in-service surveillance, research and development of energetic materials.

DESCRIPTION

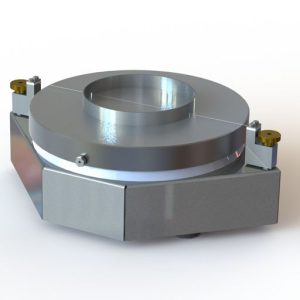

The STABIL VI® is comprised of the main unit which operates the two heavy aluminum heating blocks – each block with 10 test tube holder holes. The temperature of the block is guided by a control unit which contains a temperature controller and a limit controller. The limit controller operates an independent alarm circuit which turns off the heating unit if the temperature were to accidentally increase above a specified limit. For small testing batches only one heating block may be used if desired.

The main unit contains two temperature controllers and two safety (limit) temperature controllers (one for each heating block); a data acquisition unit (for the continuous recording of signals from one to twenty pressure transducers); a stabilized and dedicated power supply for the transducers and a data port for a personal computer. The data acquisition unit also processes signals from a barometric pressure transducer and a temperature sensor continuously measures the ambient pressure and temperature for the duration of the testing period. Two heating blocks can be operated simultaneously all at different temperatures. Up to 20 samples can be tested simultaneously with different beginning and ending of measurements. Temperature sensors in the heating blocks are calibrated and a conversion table is included in the software. WINSTAB™ software for Windows 7 continuously records and evaluates the evolution of gases generated by decomposition, evaporation or sublimation of the sample.

ADVANTAGES & FEATURES

- The unique design of the STABIL VI® completely updates and replaces all comparable old mercury-containing apparatuses and is the standard of excellence

- Automatic measurement and evaluation user-friendly software

- Continuous Pressure-Time Record and automatic calculation for Volume-Time Dependence

- Adaptability of design–the instrument and software are able to be customized

- Calibrated volumes of test tubes and pressure sensors

- Automatic temperature calibration

- 1 to 20 independent sample measurements may be conducted simultaneously

- Independent alarm circuit for monitoring of temperature (to avoid overheating)

- Rate of pressure rise and overpressure inside test tubes are monitored by WINSTAB™ software as a part of the alarm functions