תיאור

The ANALYSETTE 3 is a “shaking sieve” system in the classic sense in which an electromagnetic drive causes the sieves to oscillate in a vertical direction. The material to be sieved is periodically propelled upward off the sieve fabric and forced through the mesh of the attached test sieve as it falls back down.

- Automatic sieve analysis with sieve evaluation software AUTOSIEVE

- Quick conversion to Vibratory Micro Mill PULVERISETTE 0

- Exact entry of the sieving time via a precise digital timer

- Manual adjustment of the amplitude during sieving

- Display of the amplitude during sieving

- Ergonomically installed robust soft touchpad

- EASYTWIST sieve stack tensioner with steel-reinforced plastic bands is included

- Optimum power consumption prevents warming up of the sieving system

- Up to 10 test sieves can be used simultaneously per working cycle – allowing up to 5 sieving operations to be performed at the same time

For automatic evaluation of your sieving results

The multilingual software AUTOSIEVE for automatic evaluation, simple monitoring and documentation of your sieving results can be downloaded here and tested non-binding and free of charge for 90 days. All you have to do is to connect a laboratory analysis balance (like for example the laboratory analysis balance up to 4.1 kg, order no. 03.2600.00) and then weigh the sieves before and after sieving using differential weighing. AUTOSIEVE will do the rest. The software enables the simple saving and retrieving of empty sieve weights, both of single sieves and complete sieve sets.

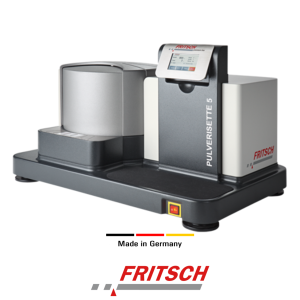

Sieving and comminution in one unit

With just a few motions, your Sieve Shaker can be transformed into the Vibratory Micro Mill PULVERISETTE 0 for grinding and homogenising small sample quantities (filling volume 1 to 10 ml, feed particle size < 5 mm). And with the special FRITSCH cryo-box, grinding is even possible at low temperatures with liquid nitrogen.

Everything you need for sieving

By default the Vibratory Sieve Shaker ANALYSETTE 3 SPARTAN is delivered incl. tensioning and the software AUTOSIEVE (90 day test version free of charge), but it does not include clamping lid, test sieves or sieve pan, which are offered in various designs and must be ordered as accessories.

Also available as an accessory is the universal sieve tensioning system TorqueMaster for automatic and reproducible tensioning of the sieve stack on the Sieve Shaker.

In order to avoid undesired contamination and extend the service life of the sieves, we recommend for gentle cleaning of the test sieves and micro-precision sieves, the FRITSCH Ultrasonic Cleaners LABORETTE 17.

| Method of analysis | sieving |

| Sieving action | Two-dimensional |

| Dry sieving | |

| Measuring range | 20 µm – 63 mm* |

| Max. sample quantity | for sieves < 63 mm: up to 2 kg*for sieves < 100 µm: up to 100 g* |

| Sieving time approx. | 3 – 20 min* |

| Wet sieving | |

| Measuring range | 20 µm – 10 mm |

| Max. sample quantity | 20 – 100 g* |

| Sieving time approx. | 3 – 10 min* |

| Further details | |

| Sieve diameter | 100 mm, 200 mm or 8" |

| Max. number of sieves per sieve stack | 10 (50 mm height)16 (25 mm height) |

| Max. weight of sieve stack | 3 kg |

| Max. height of sieve stack | 550 mm |

| Amplitude | 0.5 – 3 mm |

| Amplitude control | manual |

| Automatic sieve analysis with evaluation software AUTOSIEVE | yes |

| Convertible to Vibratory Micro Mill PULVERISETTE 0 | yes |

| Electrical details | 100-240 V/1~ 50-60 Hz, 50 Watt |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be sieved and instrument configuration) | Approx. LpAd = 63 dB |

| Weight | 21 kg |

| Dimensions (W x D x H) | bench top instrument 37 x 40 x 20 cm |